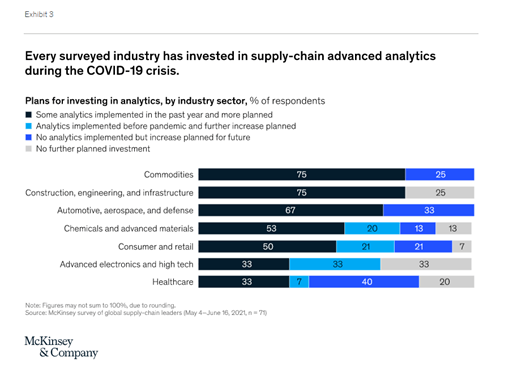

Over the past two years, distributors have had to implement new tools and processes to improve visibility to properly forecast, receive and manage their inventory to reduce lead times. According to a recent survey from McKinsey, an overwhelming majority of respondents invested in digital supply-chain technologies during the past year, with most investing more than initially planned to address disruptions. Those that chose to forego investments in technology have struggled to compete with their more agile competitors and remain vulnerable to disruptions.

Effectively managing lead times is critical for distributors to maximize cash flow and deliver a seamless customer experience. Recent supply chain disruptions combined with increasing customer demands have greatly increased lead times, resulting in major backlogs for distributors and their customers. Adopting technologies to help automate processes can help to play a major role in understanding and minimizing lead times.

Check out four processes to automate to reduce lead times and increase competitiveness and an example of process improvements from our customer Schoolhouse.

How long does it currently take your team to get customer purchase orders into your system? Are orders often delayed due to miscommunication or incorrect information?

When distributors manually receive large numbers of purchase orders, lead times increase, and errors can often prolong the process even further. Sales reps are unable to focus on value-driven tasks, resulting in lost revenue and inefficiencies.

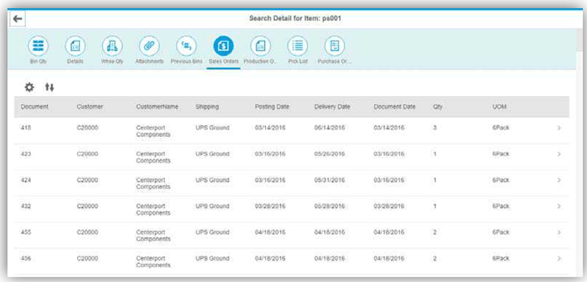

Automating order processing can help companies accelerate their order-to-cash cycle, additionally automating workflow with your trading partners with EDI or with real-time web services file exchanges both result in increased efficiency across the entire supply chain. Utilizing a cloud ERP system with Integrations, distributors can capture sales data and trigger automated workflows to fulfill, ship, and track orders to reduce lead times for customers. This prevents teams from manually entering information, reducing the number of errors and inaccuracies.

Are your orders delayed due to a limited workforce? Are your existing processes labor intensive? Are your inventory counts accurate?

Warehouse operations can make or break distributors’ lead times. Eliminating redundant, labor-intensive duties can help speed up processes, allowing you to ship orders in a timelier manner and reduce lead times for customers.

Incorporating automation into your warehouse management processes helps to streamline and integrate inventory management through the full operational life cycle of receiving, put-away, picking, packing, and shipping. Warehouse Management Solutions help distributors optimize operations by helping to eliminate lost inventory with inventory cycle counts, bin-to-bin transfers, barcode scanning, and more.

Are you relying on manual data entry to manage supply? Do you need better visibility into your company’s inventory levels? Do you lack a standardized process for forecasting demand?

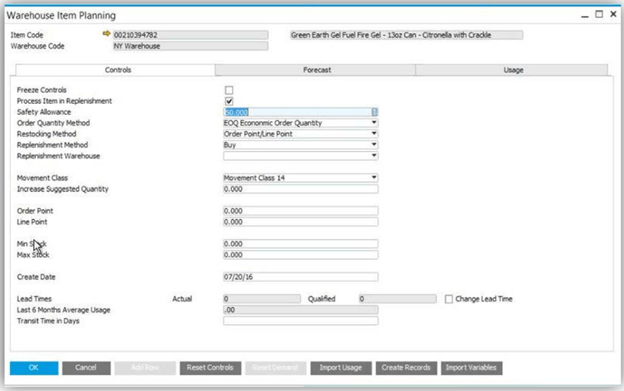

Proper inventory planning is critical in reducing lead times as it reduces stockouts and backorders, allowing distributors to fulfill orders as soon as they are placed. The process for procuring stock can be timely and resource-intensive without automation in place to support the required activities.

Automating inventory planning provides a proactive approach to procuring stock, ensuring that lead times remain as low as possible and are not impacted by insufficient inventory. The right inventory planning solution can help distributors:

By implementing a system to handle inventory planning processes, internal resources are freed up to spend time analyzing how to reduce lead times and increase efficiencies across the supply chain.

Can customer track their orders? Are they receiving real-time notifications to alert them of their order status?

Even with all of the above automation in place, uncontrollable disruptions are inevitable, which can result in extended delays and lead times. In situations like this, communication between distributors and customers is crucial.

Automating notifications to alert customers of changes in the status of their orders helps to build trust and improve the customer experience. Integrated processes like EDI and data messenger can help distributors inform customers, vendors, leads, employees, and partners when supply chain disruptions cause lead times to increase.

Many of our wholesale distribution and manufacturing customers have been severely impacted by supply chain disruptions over the past two years. Schoolhouse, a manufacturer of lighting and home goods produces made-to-order products and prioritizes minimizing lead times. With SAP Business ByDesign as their ERP, they can forecast inventory demand and recently worked with VistaVu to integrate their eCommerce platform to Shopify and SAP Business ByDesign and implemented EDI to streamline their order and fulfillment process.

This automation has improved their data frequency, which has resulted in their order and fulfillment process being timelier and more accurate. Mark Schue, Director of IT at Schoolhouse noted that “the day we implemented we only had three out of 1000+ order transactions with unexpected issues, which is an incredible feat.”

While Schoolhouse has had to manage varying lead times due to supply chain disruptions, their technology investments and automation efforts have paid off. Schue said that “with EDI, we will save hours each week by fully automating everything from purchase orders to invoicing, to shipment tracking, which will free up employees to perform other work and avoid human errors.” Read Schoolhouse’s full story here.

While making investments in technology and automation may seem daunting, it’s important to consider the value that this provides distributors. Long lead times stifle growth, reduce cash flow and negatively impact the customer experience.

Reach out to our team today to learn more about solutions to help manage supply chain disruptions and reduce lead times for your company.

VistaVu creates solutions for your business.

Offices in Calgary, Houston, Dallas, Denver, & New York.

Call us at 1-888-300-2727 ext. 105